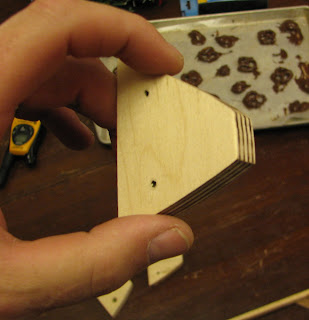

I made the first nose piece using my disk grinder then used it as a patter to make the other 4 using my router. I just screwed them together. I know that there is only 3 in the pic but the other is in the jig.

This is my plan of action on the full length ribs. Instead of cutting them short and then later adding a piece to round out the rib, I am going to make the rounded lead edge right into the rib. This should make things a little easier(????) and stronger for sure. It will allow the tip wood insert to be sandwiched in between the plywood skins. This plywood that I am using for this part is a 9 ply birch with no voids. Earlier I tried to soak it and get it to delaminate. It would not come apart at all. This might be a hint heavier than the plans version, but not enough to ever notice.